Kafan

Powder Coating Equipment Package

| Availability: | |

|---|---|

| Quantity: | |

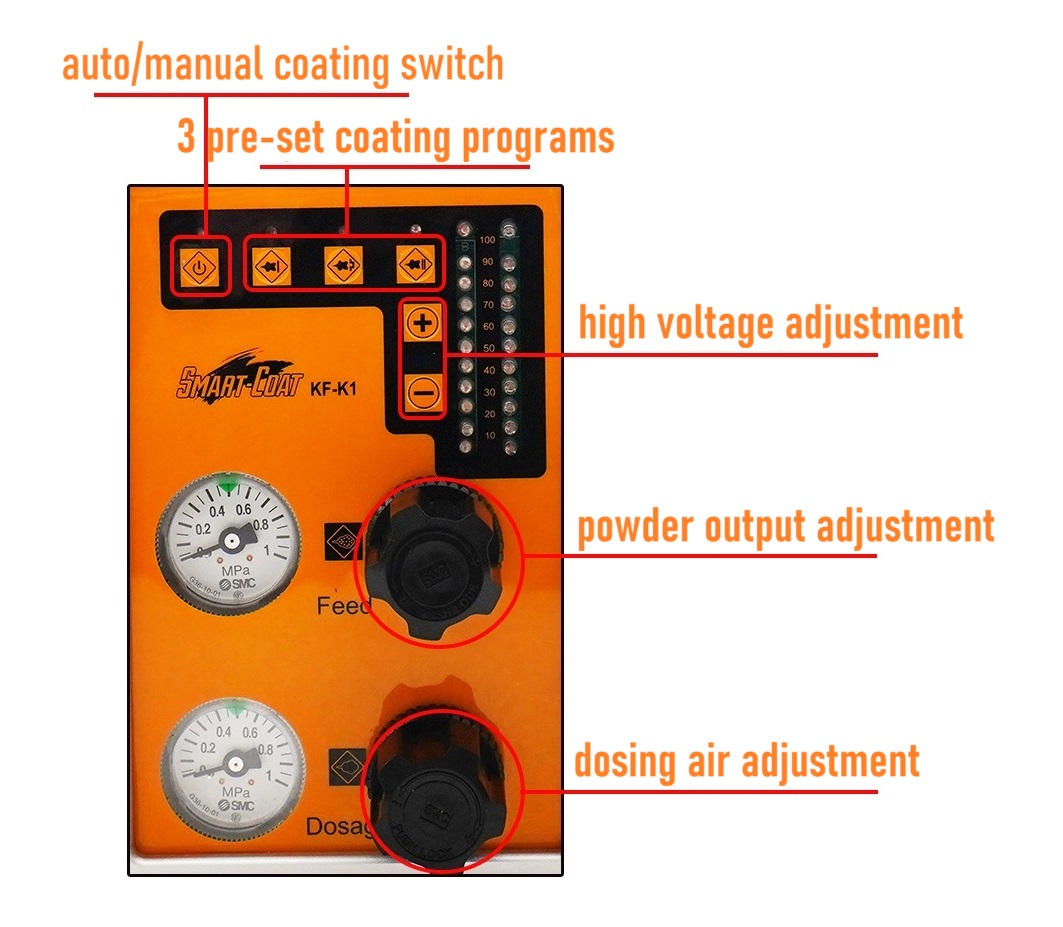

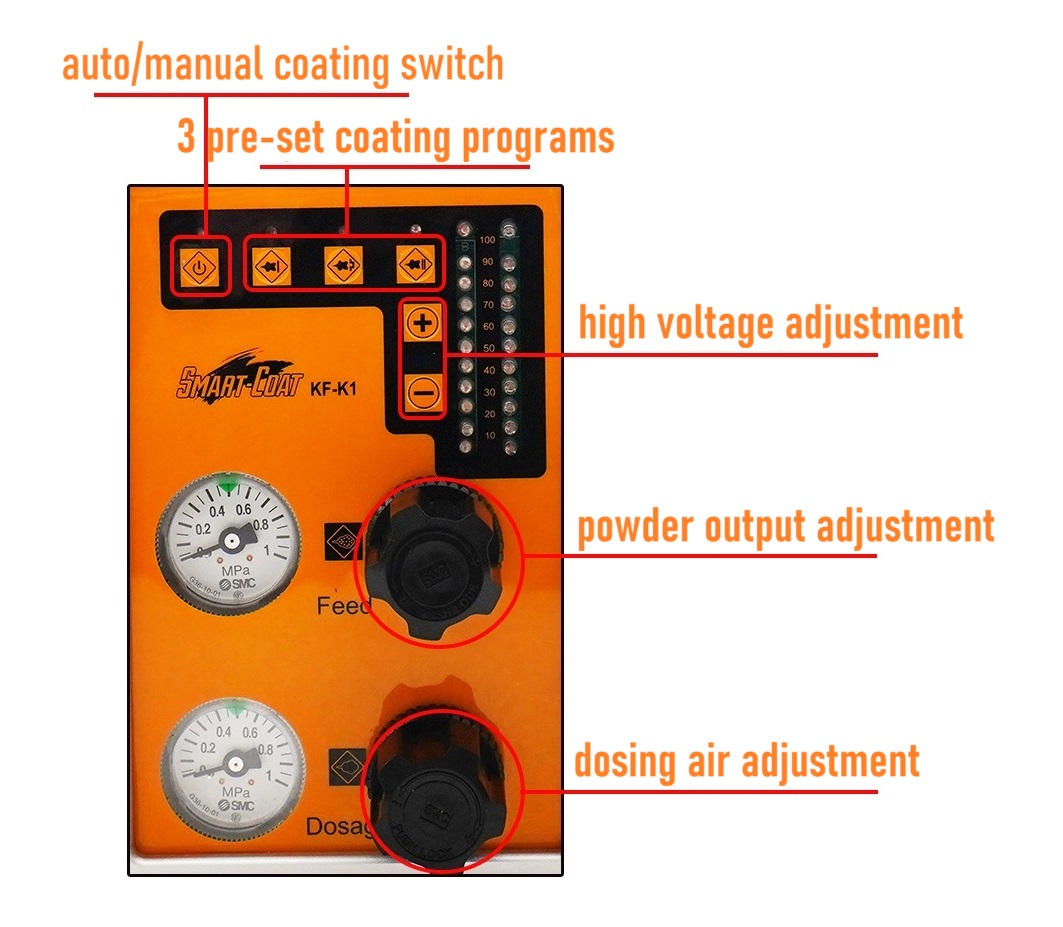

Kafan KF-K1 series powder coating machine applies the easiest spray method that delivers consistent and uniform powder output, delivers perfect coating results for whether flat shape parts or complex shape parts, increase working efficiency, reduce powder cost.

There are 3 application programs pre-set for beginners, including flat parts coating program, corner coating program, re-coating program. 0-100kv voltage adjustable by digital, help you easily find the optimal data for different applications

Our cartridge recovery powder booth is great for coating small or big sized parts, such as auto parts, furniture parts. Configured with PLC control system, 4 pcs cartridge filters, centrifugal fan. The rear-mounted filtration unit keeps your cabin clear of particulate and is perfect for batch coating operations.

| Mode | KF-2315 |

| Type | cartridge filter type |

| Working Dimension | Width2300 * Depth1500 * Height1500mm |

| Overall Dimension | Width2750 * Depth2070 * Height2180mm |

| Power Supply | Electric |

| Voltage | 220V/380V/410V, can be customized |

| Nominal Power | 4kw |

| Cartridge Filter Material | 100% polyester |

| Filter Count | 4 pcs |

| Filter Hang Type | Quick release |

| Filter Cleaning System | Pneumatic |

The powder coating oven designed with ground trolley system allows holding batch of workparts. Kafan curing oven provides uniform distribution of warm air for the parts because of the circulation fan. The 100mm thickness rock wool board always keeps the inner chamber warm. It rapidly raise to required temperature, save production time.

| Model | KF-1732 |

| Working Dimension | Width1600 * Heght1700 * Depth3200 (mm) |

| Voltage | 220V/380V(50-60Hz) |

| Power Supply | Gas/Diesel/LPG |

| Warm-up Time | 15-30min (180°C) |

| Temperature stability | < ± 3-5°C |

| Temperature max. | 250°C |

| Ventilation performance | 805-1677m3/h |

| Motor Power | 1.5kw |

| Circulation/ Air flow | Vertical ,Variable through holes on the walls |

| Transportation | Trolley |

Size and special requirements of powder coating equipment can be customized to meet your actual application.

Kafan KF-K1 series powder coating machine applies the easiest spray method that delivers consistent and uniform powder output, delivers perfect coating results for whether flat shape parts or complex shape parts, increase working efficiency, reduce powder cost.

There are 3 application programs pre-set for beginners, including flat parts coating program, corner coating program, re-coating program. 0-100kv voltage adjustable by digital, help you easily find the optimal data for different applications

Our cartridge recovery powder booth is great for coating small or big sized parts, such as auto parts, furniture parts. Configured with PLC control system, 4 pcs cartridge filters, centrifugal fan. The rear-mounted filtration unit keeps your cabin clear of particulate and is perfect for batch coating operations.

| Mode | KF-2315 |

| Type | cartridge filter type |

| Working Dimension | Width2300 * Depth1500 * Height1500mm |

| Overall Dimension | Width2750 * Depth2070 * Height2180mm |

| Power Supply | Electric |

| Voltage | 220V/380V/410V, can be customized |

| Nominal Power | 4kw |

| Cartridge Filter Material | 100% polyester |

| Filter Count | 4 pcs |

| Filter Hang Type | Quick release |

| Filter Cleaning System | Pneumatic |

The powder coating oven designed with ground trolley system allows holding batch of workparts. Kafan curing oven provides uniform distribution of warm air for the parts because of the circulation fan. The 100mm thickness rock wool board always keeps the inner chamber warm. It rapidly raise to required temperature, save production time.

| Model | KF-1732 |

| Working Dimension | Width1600 * Heght1700 * Depth3200 (mm) |

| Voltage | 220V/380V(50-60Hz) |

| Power Supply | Gas/Diesel/LPG |

| Warm-up Time | 15-30min (180°C) |

| Temperature stability | < ± 3-5°C |

| Temperature max. | 250°C |

| Ventilation performance | 805-1677m3/h |

| Motor Power | 1.5kw |

| Circulation/ Air flow | Vertical ,Variable through holes on the walls |

| Transportation | Trolley |

Size and special requirements of powder coating equipment can be customized to meet your actual application.