Views: 86 Author: Site Editor Publish Time: 2018-11-21 Origin: Site

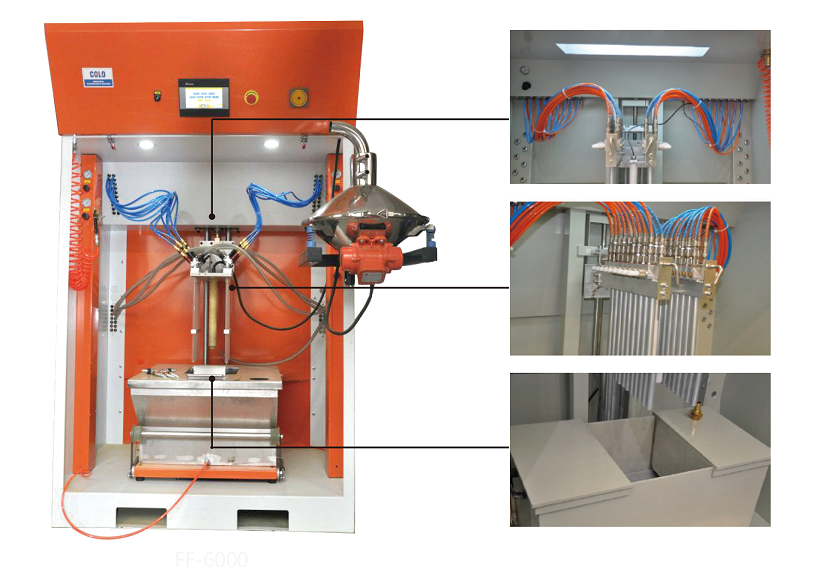

1.PLC Control System

2.Touch Screen Operation Interface

3.Powder Position Tracking

4.Absolute Position Induction

5.Powder Suction Tube Vertical Lifting

6.Powder Recovey & Sieving Control

7.Automatic Powder Cleaning Device

8.Powder Hopper Vibrating & Fluidzing System

Continuously, uniformly, quantificationally feed the powder to the spray gun, usually applied in an automatic powder coating line to improve quality and efficiency.

Incorprating a lifting venturi-injector stage with powder detector, no matter low or high of the powder position, the suction tube always stay in an optimal fluidizing area, ensure the powder feeding quality

The injector stage lifter use anti-dust,stable lifting air cyclinder.

The substrate of the microporous plate is meticulous and uniform, in good fluidizing function.

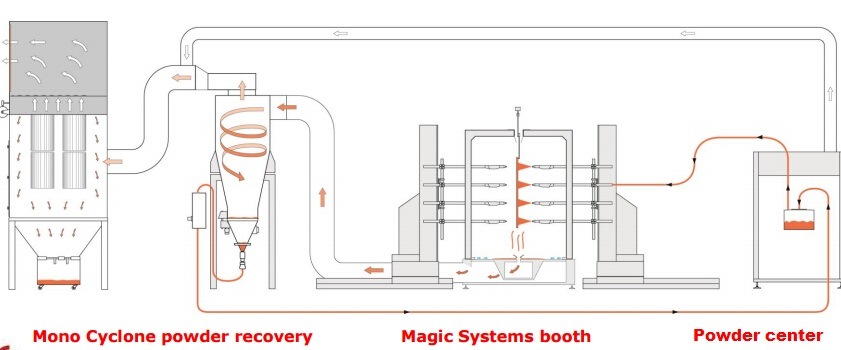

Installed with vibration powder sieving machine, ensures the purity of recovery powders, which could mix with fresh powders in proportion for recycling. Such design increases the powder utilization and save cost.

The controlling system will alarm once lack of powder, warning operators to feed powders in time

PLC programming control, touch screen operation, convenient for debugging and user-friendly.

There is a pulse-jet device that automaticlly clean spray gun and pipeline rapidly, at the same time if this device is connected with cyclone system, it will make the powder feeder chamber in negative pressure, creating clean working condition and achieving fast color change.