Views: 30 Author: Site Editor Publish Time: 2018-05-22 Origin: Site

Here I will tell you the advantages of powder coating and differences between painting and powder coating. After read it, you will get clear why choose powder coating for surface finishing

Powder coating is enviromemtal protective

Powder coating powders is a kinds of solid coating, not contain solvent, and has no volatile toxic gases during working process. Powder coating cause no pollution to the environment and no harm to human health, which is typically superior to painting. Some applications occasion have definitely request that must use electrostatic powder coating, such as children’s furniture.

High effeciency by one-step coating.

Powder curing requires shorter time, 15-20 minutes varies from different type powders, wet painting drying requires 15-60 minutes, varies from different paintings.

Powder curing requires less time

Powder coating can reach 60-150μm thickness film in one-time-spray, while wet paint spray only reach 15-30μm one time. The adhesion, corrosion resistance, aging resistance and mechanical properties of powder-coated products is much more outstanding than painted parts. The powder coating achieves elegant and quality appearance

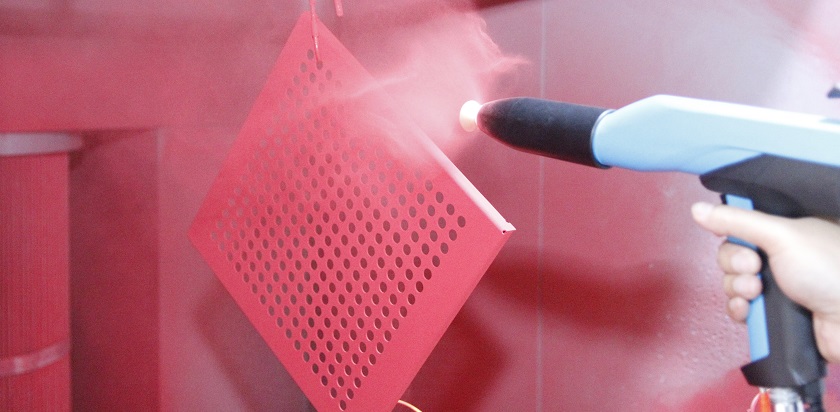

Powder coating is an easy processing job

Powder coating is one-step covering, not like traditional painting that needs primer. Powder coating is an easy job, does not require high technology, Kafan powder coating machine is also simple operated equipment.

More budget saving than painting

The cost of powder coating is much lower than the same effect of painting process. The powder utilization rate of powder is up to 95%, and oversprayed powder can be recycled for further use.

Vast prospect of electrostatic powder coating

The development of electrostatic powder coating is rapid. In addition to various effects such as hammer marks, orange prints, matte, gloss, cracks, flash gold, and flash silver, in recent years. also appears high temperature resistant powders, low temperature resistant powders, weather-resistant ability powders, water-resistant powders, acid-resistant powders, low-temperature-curing powders, UV-curing powders, etc, which makes vast and colourful prospect of electrostatic powder coating.

Choose Kafan powder coating equipment for application

The powder coating is widely used for car rims, alloy wheels, aluminum profiles, and other various metal products. Choose Kafan high quality powder coating equipment, intelligent system for both beginners and specialists, simple structured and easy to use.